What are Cable Carriers?

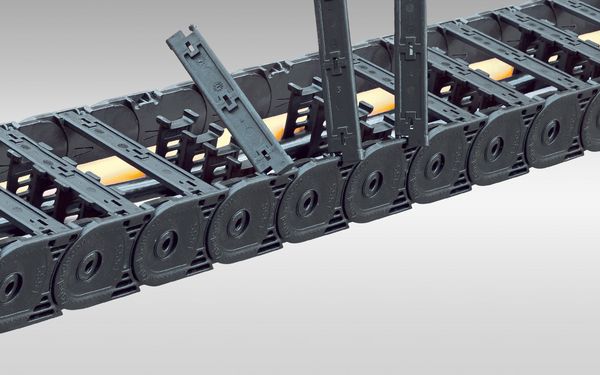

Cable carriers, also known as cable chains or drag chains, are modular protective systems designed to guide and protect cables and hoses in moving machinery. They prevent cable tangling, reduce wear, and organize multiple cables in applications with repetitive motion, ensuring reliable operation and extended cable life.

Key Benefits:

- Protect cables from damage, abrasion, and environmental factors

- Organize multiple cables and hoses in a single compact system

- Extend cable service life by up to 10x compared to unsupported cables

- Reduce maintenance costs and minimize equipment downtime

- Support smooth, controlled cable movement in dynamic applications

Common Applications:

- Automated machinery and industrial robotics

- CNC machines and precision manufacturing equipment

- Material handling systems and conveyor belts

- Medical equipment and laboratory automation

- Packaging lines and food processing systems

Professional Cable Carriers

Reliable energy chain systems for dynamic industrial applications

Choose Your Ideal Cable Carrier Solution

Industry-leading cable management systems engineered for reliability, performance, and long-term value

Plastic Cable Carriers

The smart choice for cost-effective, reliable cable management. Perfect for standard industrial applications.

Steel Cable Carriers

Unmatched durability for extreme conditions. The ultimate solution when reliability is non-negotiable.

Plastic vs Steel Cable Carriers: Complete Comparison

Choosing between plastic and steel cable carriers depends on your application requirements. Here's a comprehensive comparison to help you decide.

| Feature | Plastic Cable Carriers | Steel Cable Carriers |

|---|---|---|

| Weight | Lightweight (50-70% lighter) | Heavy-duty construction |

| Load Capacity | Light to medium loads (up to 50 kg/m) | Heavy loads (up to 500+ kg/m) |

| Noise Level | Silent operation (40-50 dB) | Moderate noise (60-70 dB) |

| Corrosion Resistance | Excellent (immune to rust) | Requires coating/maintenance |

| Temperature Range | -40°C to +120°C | -60°C to +350°C |

| Price Range | Cost-effective (30-40% lower) | Premium investment |

| Maintenance | Minimal required | Regular lubrication needed |

| Best For | Cleanrooms, high-speed automation, electronics | Heavy machinery, harsh environments, long travels |

How to Choose:

- →Choose Plastic if you need lightweight, silent operation, and corrosion resistance for standard applications

- →Choose Steel if you require maximum load capacity, extreme temperature resistance, or very long travel lengths

Find Your Perfect Cable Carrier Solution

Use our powerful tools to configure or filter the ideal cable carrier system for your application

Cable Carrier Configurator

Design your custom cable carrier system step-by-step with our interactive tool

Cable Carrier Filter

Find the perfect cable carrier by filtering based on your specific requirements

Ready to Optimize Your Cable Management?

Contact our expert team to discuss your specific requirements and find the perfect cable carrier solution