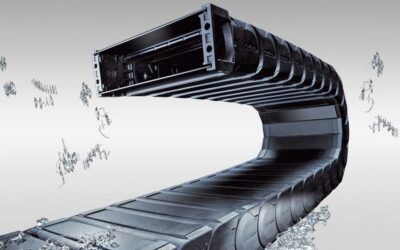

In modern machine building, reliability, efficiency, and safety are paramount. An essential yet often underestimated component is the energy chain (also known as a cable carrier). Energy chains ensure controlled cable guidance in moving applications, protecting cables from wear, kinking, and failures.

Where exactly are energy chains used, and why are they indispensable? This article covers the most common applications and core benefits.

What is an energy chain?

An energy chain is a mechanical guidance system that organizes and protects moving cables and hoses. Typical use cases include machines with moving axes, robots, and machining centers.

Want to know which energy chain best fits your machine? Request a no-obligation consultation.

Key applications in machine building

CNC machines and machining centers

CNC equipment demands consistent, precise cable routing. Energy chains let data lines, coolant hoses, and power cables travel smoothly without tangling or damage.

Benefits: prevents cable failures, increases machine reliability, reduces maintenance costs.

Curious about CNC-specific solutions? Use our energy-chain selector.

Automation lines and conveyors

Production lines often involve long travel distances. Energy chains guide cables for sensors, motors, and actuators safely along the motion path, avoiding kinks and abrasion.

Typical choice: long-travel chains, robust outer jackets, optional damping inserts.

Industrial robots

With multiple moving axes, robots place high demands on cable management. Energy chains support smooth, precise motion and limit cable strain during frequent rotation or swiveling.

Plus: can be combined with damping elements to reduce vibration and noise.

Gantry and pick-and-place systems

For long linear strokes, reliable energy chains prevent cable faults that could cause downtime or product damage.

Special environments: cleanrooms and food-grade machinery

For high-hygiene applications, chains made of special plastics or stainless steel are easy to clean and minimize contamination risks.

Why energy chains are essential

Reliability: fewer faults and unplanned stops.

Cost savings: reduced wear and maintenance, longer cable life.

Safety: better protection for personnel and equipment.

Scalability: suitable for virtually any motion and travel length.

Conclusion: The quiet enabler in your machine park

Often out of sight, energy chains are critical to machine performance. From CNC mills and robot arms to full conveyor lines, reliable cable guidance is the foundation for top results.

Want a fast match for your application?

Contact our specialists or use the energy-chain selector.

Related Products

Our Product Categories

Cable Carriers

High-quality energy chain systems designed for reliable cable management in dynamic industrial applications.

Learn MoreOur Product Categories

Flexible Cables

Premium cables engineered for continuous movement and demanding industrial environments worldwide.

Learn MoreOur Product Categories

Cable Conduits

Durable protective conduit solutions ensuring secure and efficient cable routing for all industries.

Learn MoreInterested in our solutions?

Get in touch with our team to discuss your cable management needs.

Contact Us