In a world where machines are becoming faster, smarter, and more reliable, it’s often the smallest components that make the biggest difference. One of those components is the cable carrier. Though often overlooked, it plays a critical role in modern automation.

This article explains why cable carriers are indispensable in today’s automated systems and how they contribute to efficiency, reliability, and innovation.

1. Reliable cable management in dynamic systems

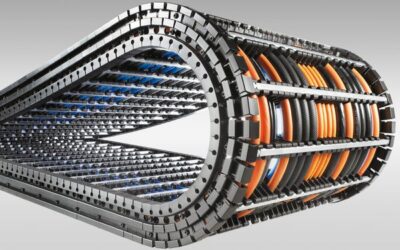

In automated production lines, cables and hoses are constantly in motion — think of robots, gantry arms, or pick-and-place systems. Without proper guidance, cables can twist, break, or cause malfunctions.

Cable carriers keep cables neatly in place, maintain a controlled bend radius, and prevent wear, ensuring long-lasting and trouble-free machine operation.

2. A key part of predictive maintenance

Predictive maintenance is one of the biggest trends in industrial automation. By using components that are reliable and easy to service, companies can minimize downtime.

Cable carriers support this by reducing cable wear and being easy to inspect or replace. Advanced models can even include sensors for real-time monitoring.

3. Faster machines, higher demands

As machines move faster and with greater precision, the demands on cable management increase. At high speeds or accelerations, a loose cable can cause vibration or damage.

A well-designed cable carrier ensures stable, repeatable motion — even at high speed — making it essential for high-performance machines.

4. Suitable for every industry and environment

From food processing and cleanrooms to offshore installations and AGVs, cable carriers come in a variety of materials and designs.

Examples:

Stainless steel for hygienic environments

Wear-resistant plastic for continuous 24/7 operation

This versatility makes them suitable for virtually any automated setup.

5. Supporting modular and scalable automation

Modern factories are flexible: machines are frequently adapted, moved, or expanded. Cable carriers make this possible. They are modular, easy to extend, and adaptable to new cable configurations.

They form a durable, scalable solution for smart, flexible production systems.

Conclusion: Small component, big impact

In a world demanding faster, smarter, and more reliable production, cable carriers are indispensable. They protect cables, improve reliability, enhance motion, and reduce maintenance costs — exactly what modern automation needs.

Need help choosing the right cable carrier?

Start the cable carrier filter and find the ideal solution.

Related Products

Our Product Categories

Cable Carriers

High-quality energy chain systems designed for reliable cable management in dynamic industrial applications.

Learn MoreOur Product Categories

Flexible Cables

Premium cables engineered for continuous movement and demanding industrial environments worldwide.

Learn MoreOur Product Categories

Cable Conduits

Durable protective conduit solutions ensuring secure and efficient cable routing for all industries.

Learn MoreInterested in our solutions?

Get in touch with our team to discuss your cable management needs.

Contact Us